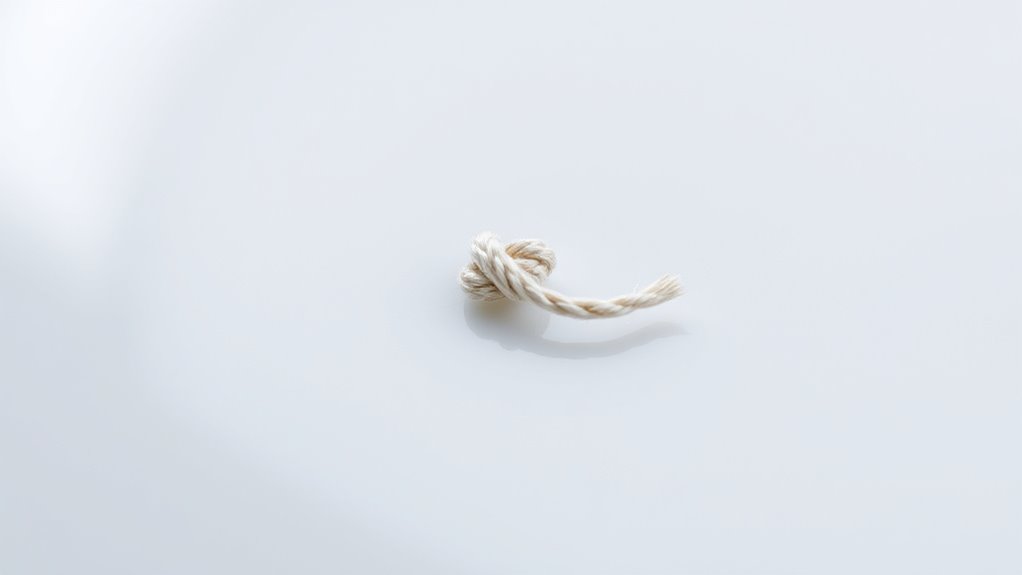

When examining micro-knots under a loupe, focus on their consistency, symmetry, and tightness. Look closely for even tension, well-formed shapes, and uniform size. Check for fraying, gaps, or loose wraps, as these can compromise strength. Notice the surface finish—smooth, glossy knots reflect good craftsmanship, while irregularities suggest flaws. Paying attention to slight color variations can reveal quality issues. Keep exploring, and you’ll uncover more details to truly assess knot quality.

Key Takeaways

- Examine knot symmetry and uniformity to assess craftsmanship and consistency under magnification.

- Check for irregular tension, loose wraps, or gaps indicating potential weakness or poor knot formation.

- Inspect surface finish for smoothness, gloss, and absence of rough patches or fraying.

- Look for color variations or inconsistencies that may reveal uneven dyeing or material flaws.

- Identify any irregularities such as asymmetry, loose fibers, or surface irregularities to evaluate overall quality.

Examining Knot Consistency and Uniformity

When examining micro‑knots under a loupe, it’s essential to assess their consistency and uniformity. Start by observing the thread consistency; evenly spun, smooth threads tend to create more predictable knots. Names inspired by famous personalities Look closely at the knot symmetry—well-formed knots will mirror each side, with loops and wraps evenly aligned. Irregularities in thread tension or uneven wrapping can lead to asymmetrical knots, which might compromise strength or functionality. Consistent thread thickness ensures uniform knot formation, making it easier to evaluate their quality. Properly symmetrical knots indicate careful tying, while irregularities could suggest hurried or imprecise work. Paying attention to these details helps you determine the overall integrity of the micro‑knots and their suitability for your application. Additionally, understanding knot strength can guide you in assessing their durability and performance. Recognizing how thread tension influences knot stability is crucial for ensuring reliable results in delicate work. For this reason, visual inspection techniques are valuable tools for maintaining high standards in detailed craftsmanship. Moreover, routinely inspecting knot uniformity helps maintain high standards in detailed craftsmanship.

Assessing Tension and Tightness

You can tell how tight a knot is by looking for firmness indicators, like the absence of slack or looseness. Tension consistency clues, such as even spacing and uniform tension across similar knots, help guarantee your work is secure. Paying close attention to these details makes it easier to assess if your knots will hold under pressure. Additionally, inspecting for knot integrity can provide insights into proper knot tension and security, ensuring your camping gear remains reliable during outdoor activities. Recognizing how visual assessment techniques and safety measures impact the reliability of knots can also be useful when evaluating visual setups for optimal viewing.

Knot Firmness Indicators

Evaluating knot firmness involves observing specific indicators that reveal the tension and tightness of the knot. You want to gauge how well the knot holds under pressure, which impacts knot durability. Pay attention to these key signs:

- The thread’s elasticity: a firm knot shows minimal stretching, indicating proper tension.

- The presence of slight slack: too much slack suggests the knot isn’t tight enough.

- The compactness of the knot: tightly packed knots often reflect good tension.

When the thread feels stiff and retains its shape, it signals a secure, durable knot. Loose or overly elastic threads may compromise knot strength, risking failure. Careful examination of these indicators helps ensure your knot is both tight and resilient. Additionally, understanding the structural integrity of the knot can guide you in making necessary adjustments to achieve optimal tension. Recognizing the exfoliating properties of glycolic acid can also assist in maintaining healthy skin around your knots, especially if irritation occurs. Being aware of knot tension assessment techniques can further improve your ability to evaluate and ensure knot security. Incorporating regular inspection practices can help detect early signs of loosening or strain, prolonging the lifespan of your knots.

Tension Consistency Clues

Observing tension consistency requires carefully comparing different parts of the knot under magnification. Look for uniform thread tension across the entire knot; uneven tension can cause variations in tightness. Tight sections will appear more compact, with less slack, while loose areas may show slight gaps or looseness. Consistent thread tension indicates a well-executed knot, with even knot tightness throughout. If certain segments seem slack or overly tight, it suggests inconsistent tension during tying. Pay attention to how the threads lie—smooth, even thread tension produces a neat, symmetrical appearance. Variations in tightness may also hint at differences in tension applied during tying or potential weakening of the thread. Recognizing these tension clues helps you assess the knot’s overall integrity and craftsmanship. Additionally, understanding automation’s role in business intelligence can aid in developing techniques for precise tension control during knot tying. Incorporating advanced tension measurement tools can further enhance your ability to evaluate and replicate perfect tension in intricate knots. A thorough analysis of tension consistency can also reveal hidden weaknesses, guiding improvements in knot-tying techniques and ensuring durability.

Analyzing Knot Placement and Alignment

Analyzing knot placement and alignment under a loupe requires careful attention to detail, as small deviations can affect the knot’s overall function and appearance. Check that the knot is centered and consistent with the thread color, avoiding uneven or skewed placement. Proper alignment ensures the knot’s durability and aesthetic harmony. Look for these key points:

- Consistent knot size, indicating even tension during formation

- Precise placement relative to other knots or design elements

- Symmetry in alignment, avoiding twists or misorientation

Pay close attention to how the thread color interacts with the knot’s position, as subtle shifts can highlight craftsmanship or flaws. Proper alignment is essential for both the strength and visual appeal of your micro‑knots.

Checking for Fraying and Wear

Have you checked your micro‑knots for fraying or signs of wear lately? Look closely for thread discoloration, which indicates aging or exposure to elements. Frayed edges suggest material degradation, weakening the structure. Use a loupe to examine the thread surface for tiny splits or loose fibers. Consistent wear may cause knots to lose their strength, risking failure. Here’s a quick reference:

| Sign of Wear | What to Look For | Potential Cause |

|---|---|---|

| Thread Discoloration | Faded or darkened threads | Material aging or exposure |

| Fraying Edges | Loose fibers or unraveling | Excessive tension or friction |

| Thin or Worn Areas | Reduced thread thickness | Material degradation |

| Loose Knots | Knots slipping or loosening | Improper tying or wear |

| Abrasion Marks | Surface scratches or worn spots | Friction against surfaces |

Regular checks help maintain knot integrity and durability.

Observing the Surface Finish and Smoothness

Since the surface finish directly affects the knot’s overall appearance and durability, it’s essential to examine it closely with a loupe. Look for variations in surface gloss, which indicate differences in how the material reflects light and reveals quality. The finish texture provides clues about the craftsmanship and handling process, showing whether the surface is smooth or rough. Pay attention to these key points:

- Consistent surface gloss suggests uniformity and good finishing.

- Smooth finish texture indicates careful craftsmanship and durability.

- Irregularities or dull patches may signal imperfections or poor processing.

Identifying Variations in Thread or Material Color

Variations in thread or material color can reveal important details about the quality and integrity of a micro-knot. Look closely for subtle color variations that indicate uneven dyeing or inconsistent thread shading. Consistent color suggests uniform material, while irregularities may signal inferior quality or potential weaknesses. Notice any areas where the thread appears darker or lighter; these are signs of color variation often caused by different dye batches or material inconsistencies. Pay attention to how the thread shading shifts across the knot—smooth shifts indicate good craftsmanship, while abrupt changes might point to inferior materials or handling. Recognizing these nuances helps you assess the durability and authenticity of the micro-knot, ensuring you’re making informed observations based on visual cues.

Detecting Any Signs of Looseness or Gaps

When inspecting micro-knots, look carefully for any signs of looseness or gaps that could compromise their integrity. Use your loupe to identify subtle indicators like uneven tension or small spaces between threads. Recognizing these details early helps guarantee your knots stay secure and durable.

Visual Inspection Tips

To effectively identify looseness or gaps in micro-knots, you should carefully examine the knots under magnification, paying close attention to the tightness of each wrap and the alignment of the fibers. Focus on the consistency of thread thickness—uneven sections may indicate looseness. Check for knot symmetry; a well-made knot should be balanced on all sides. Look for any irregularities that suggest gaps or uneven tension. Keep these tips in mind:

- Ensure the wraps are uniformly tight around the core

- Verify the fibers are aligned and not frayed or separated

- Observe the overall symmetry of the knot for signs of imbalance

A sharp eye on these details helps confirm the knot’s integrity and prevents future issues.

Spotting Looseness Indicators

Detecting looseness or gaps in micro-knots requires a keen eye for subtle irregularities. Look closely at thread tension—uneven tension can cause loose spots or gaps. Check for knot symmetry; irregularities suggest compromised security. Use a loupe to examine these indicators:

| Indicator | What to Look For | Why It Matters |

|---|---|---|

| Uneven thread tension | Looser or tighter sections | Indicates potential slack |

| Asymmetrical knots | Unequal loop sizes | Suggests compromised strength |

| Gaps or spaces | Visible openings between threads | Risk of knot failure |

| Loose thread ends | Frayed or slack ends | Possible entry points for gaps |

| Irregular knot shape | Misshapen or uneven knots | Signs of poor tension control |

Recognizing Gaps or Gaps

Gaps or spaces between threads can indicate looseness or potential failure in a micro-knot. When examining closely, look for areas where the threads aren’t tightly packed or where small gaps appear. These gaps may reveal issues like inconsistent thread color variations, which can signal uneven tension, or knot size discrepancies, suggesting the knot might be compromised. To detect these signs effectively, focus on:

- Variations in thread color that break the uniformity

- Visible gaps that suggest looseness

- Unequal knot sizes indicating uneven tension

These clues help you identify weak points or loose sections that could lead to knot failure. Recognizing these signs early allows for corrections before the knot’s integrity is compromised, ensuring a secure and durable finish.

Evaluating the Overall Craftsmanship and Precision

When examining micro-knots under a loupe, evaluating craftsmanship and precision involves more than just identifying visible flaws; it requires a keen eye for subtle details. You should assess how consistent and tight the knots are, which reflects skill and attention to detail. Material selection greatly impacts longevity and appearance, while tool quality influences the accuracy of the work. A well-crafted knot exhibits uniform tension, smooth progressions, and minimal irregularities. The table below highlights key aspects to contemplate:

| Aspect | Indicator | Importance |

|---|---|---|

| Material selection | Durable, suitable fibers | Affects longevity and appearance |

| Tool quality | Sharp, precise tools | Ensures accuracy and consistency |

| Knot symmetry | Uniform size and shape | Indicates craftsmanship |

| Tension control | Even, tight knots | Ensures durability |

| Finishing details | Clean edges, no loose ends | Reflects meticulous work |

Noticing Irregularities and Deviations From Pattern

Irregularities and deviations from pattern become evident when you scrutinize micro-knots under a loupe, revealing subtle inconsistencies that can compromise both appearance and durability. Look closely at the color contrast within the knots; uneven shading may indicate atypical material application. Pay attention to the material texture—areas that feel rougher or smoother than expected can signal flaws. Deviations often appear as misaligned loops or inconsistent tension, disrupting the overall pattern. To identify these issues, focus on:

- Variations in color contrast that disrupt uniformity

- Irregularities in material texture, such as roughness or smoothness

- Misaligned or uneven knot placement that breaks the pattern

Recognizing these irregularities ensures you assess craftsmanship accurately and catch potential weaknesses early.

Frequently Asked Questions

How Can I Distinguish Between Genuine and Counterfeit Micro‑Knots?

To tell if micro‑knots are genuine or counterfeit, you should examine the authentication markers closely. Genuine micro‑knots often display consistent, high-quality material and precise knotting techniques. Counterfeit versions may show uneven knots, inconsistent thread tension, or inferior material. Pay attention to the material consistency; authentic micro‑knots use uniform, durable threads, while fakes might have irregular fibers or poor craftsmanship. This careful inspection helps guarantee authenticity.

What Tools Are Best for Inspecting Micro‑Knots Under a Loupe?

When inspecting micro‑knots under a loupe, you want the best tools to see details clearly. Choose a loupe with adjustable magnification options, ideally between 10x to 30x, to examine knot intricacies. Use proper lighting techniques, like LED or fiber optic lights, to eliminate shadows and enhance visibility. A high-quality loupe with bright, even illumination helps you distinguish genuine from counterfeit knots effectively.

How Does Environmental Humidity Affect Knot Integrity?

Humidity effects on knot durability are like a sponge soaking up water—too much moisture weakens the fibers. When humidity rises, it can cause micro‑knots to loosen or become brittle, reducing their strength over time. You should monitor environmental humidity carefully, as fluctuating levels can compromise knot integrity. Maintaining a stable, moderate humidity helps preserve knot quality, ensuring your work stays secure and durable in various conditions.

Are There Specific Signs of Aging in Micro‑Knots?

When checking micro‑knots, look for aging indicators like knot deterioration, which shows signs of weakening or fraying. These aging signs can include a loss of elasticity, discoloration, or slight fraying around the knot area. Recognizing these indicators helps you assess the knot’s durability. If you notice any deterioration, it’s a good idea to contemplate retying or reinforcing the knot to guarantee it maintains its strength and performance.

Can Micro‑Knots Be Repaired Without Visible Damage?

You can often repair micro-knots without visible damage by carefully selecting the right knot material and using precise repair techniques. When you identify minor issues, you can re-thread or tighten the knot, ensuring the original appearance remains intact. Employing gentle handling and appropriate tools helps you maintain the knot’s integrity, making the repair seamless. With patience, you can restore micro-knots effectively while keeping them virtually undetectable.

Conclusion

By closely examining micro‑knots under a loupe, you’re like a detective uncovering hidden clues. Pay attention to consistency, tightness, and craftsmanship to guarantee quality. Spotting irregularities is like finding knots in a well-woven tapestry—disruptions that stand out. With practice, you’ll become a skilled artisan, confidently catching tiny imperfections before they unravel your work. Remember, every detail you observe is a stitch in the fabric of expert craftsmanship.