Silk-on-silk weaves at 1,200 KPSI showcase exceptional craftsmanship that blends traditional techniques with modern technology. By increasing knot density and carefully selecting high-quality fibers, artisans create ultradense, lustrous fabrics with vibrant colors and smooth textures. Combining meticulous handwork with advanced machinery guarantees precision and durability. If you want to discover how these intricate, innovative fabrics come to life and the skills behind them, there’s more to explore beyond the surface.

Key Takeaways

- Achieving 1,200 KPSI+ involves meticulous knotting, tension control, and advanced weaving techniques to create ultradense, durable silk-on-silk textures.

- High knot density enhances fabric strength, vibrancy, and intricate pattern detail, showcasing exceptional craftsmanship.

- Traditional weaving methods are combined with modern machinery like automated looms and digital design tools for precision.

- Material selection, including high-quality silk and colorfast dyes, is critical for maintaining density, color richness, and longevity.

- Innovations in dyeing, micro-weaving, and sustainable fibers continue to push the boundaries of ultradense silk craftsmanship.

The Evolution of Silk Weaving Techniques

The evolution of silk weaving techniques reflects centuries of innovation and cultural exchange. You can see this history in the progression from simple, hand-loomed fabrics to highly sophisticated methods. Historical techniques like brocade, satin, and damask showcase the skill and artistry passed down through generations. Cultural influences played a crucial role, blending local traditions with external ideas brought through trade routes such as the Silk Road. As you examine ancient textiles, you notice patterns and textures that reveal diverse origins and technological advancements over time. Each era contributed to refining weaving methods, leading to the complex, dense silk weaves we see today. This ongoing evolution embodies a rich tapestry of cultural exchange, technological progress, and artistic expression. Notably, innovations in weaving density have allowed for the creation of fabrics with exceptional durability and luster, elevating the artistry of silk craftsmanship. Additionally, advancements in textile technology have further enhanced the quality and complexity of contemporary silk weaves, reflecting the continuous development of craftsmanship techniques over centuries. Furthermore, modern research into fiber manipulation techniques continues to push the boundaries of what is possible in silk weaving, ensuring this art form remains both innovative and deeply rooted in tradition.

Achieving Ultradense Textures: The Role of Knot Density

Higher knot density directly influences the durability and richness of silk-on-silk weaves. By increasing knot counts, you can create ultradense textures that enhance both strength and visual complexity. Mastering specific techniques allows you to push these textures even further, achieving exceptional craftsmanship. Incorporating high-quality materials is essential for maximizing the benefits of dense weaves and ensuring lasting beauty. Additionally, understanding ethical hacking principles can help protect these valuable textiles from digital threats, preserving their cultural significance. Paying attention to color accuracy during the weaving process can further elevate the vibrancy and realism of the finished piece. Emphasizing fiber quality also plays a crucial role in the overall integrity and appearance of the final textile. Recognizing the importance of material sustainability can contribute to environmentally responsible craftsmanship and long-term preservation.

Knot Density Impact

Ever wondered how artisans achieve the ultradense textures in silk-on-silk weaves? It all comes down to knot density. When you increase the number of knots per inch, you create a tighter weave that enhances fiber strength, making the fabric more durable. This high knot density also affects dye penetration; thicker, closely packed knots limit how dyes seep into the fibers, resulting in richer, more vibrant colors. You’ll notice that as knot density rises, the fabric becomes more compact and resilient, allowing light to reflect precisely and giving the weave its signature sheen. Achieving these effects requires balancing knot density to optimize fiber strength without compromising dye absorption. Understanding knot density] can also offer insights into the harmony and flow of the weaving process, guiding artisans toward achieving the perfect balance. The result is a luxurious, ultradense silk that showcases expert craftsmanship at every inch.

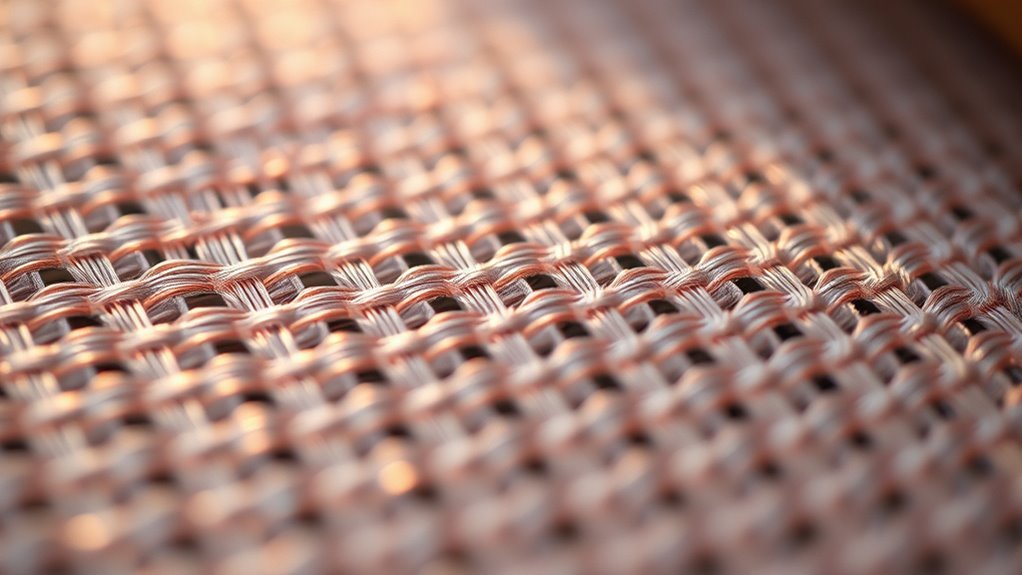

Techniques for Ultradense Weaves

To achieve ultradense silk-on-silk textures, artisans carefully employ specific knotting techniques that maximize knot density without sacrificing fabric quality. They often utilize meticulous, repetitive knotting patterns, increasing thread interlacement to reach 1,200 KPSI+. Proper dyeing techniques are vital; artisans select dyes that penetrate deeply, ensuring vibrant, uniform colors. They also address colorfastness issues by using natural mordants and controlled dyeing processes, preventing fading over time. These methods allow for tightly woven structures that resist wear and maintain their intricate appearance. Mastery of tension control during knotting and dyeing guarantees consistent density and color stability. Additionally, understanding the importance of Hackathons can inspire artisans to collaborate on innovative textile techniques and share knowledge rapidly, fostering continuous improvement. Incorporating advanced dyeing techniques can further enhance the vibrancy and longevity of the silk weave. For example, employing collaborative innovation methods encourages the exchange of traditional and modern practices, pushing the boundaries of textile craftsmanship. Ultimately, these techniques enable the creation of ultradense weaves that combine durability with exquisite detail, elevating silk-on-silk craftsmanship to extraordinary levels.

Traditional Craftsmanship Meets Modern Technology

Traditional craftsmanship in silk weaving has seamlessly integrated with modern technology, enhancing both precision and efficiency. By combining age-old techniques with advanced machinery, artisans preserve the essence of historical silk while elevating production standards. This synergy allows for intricate patterns rooted in cultural symbolism to be recreated with greater accuracy at ultra-high densities. Modern tools help maintain the delicate balance between tradition and innovation, ensuring that each weave reflects the rich history behind silk art. You can now see how time-honored skills adapt to contemporary demands, blending cultural significance with technological progress. Additionally, understanding signs of spoilage in natural materials helps ensure that the high-quality silk remains preserved during production and storage. Embracing technological advancements in weaving not only safeguards cultural heritage but also opens new possibilities for creative expression and durability in high-KPSI weaving. This fusion not only preserves the legacy of silk craftsmanship but also pushes the boundaries of what’s possible in high-KPSI weaving. Incorporating modern quality control methods further enhances consistency and excellence in the final products. Moreover, leveraging AI-based monitoring can optimize the weaving process by detecting defects in real time, ensuring superior product quality.

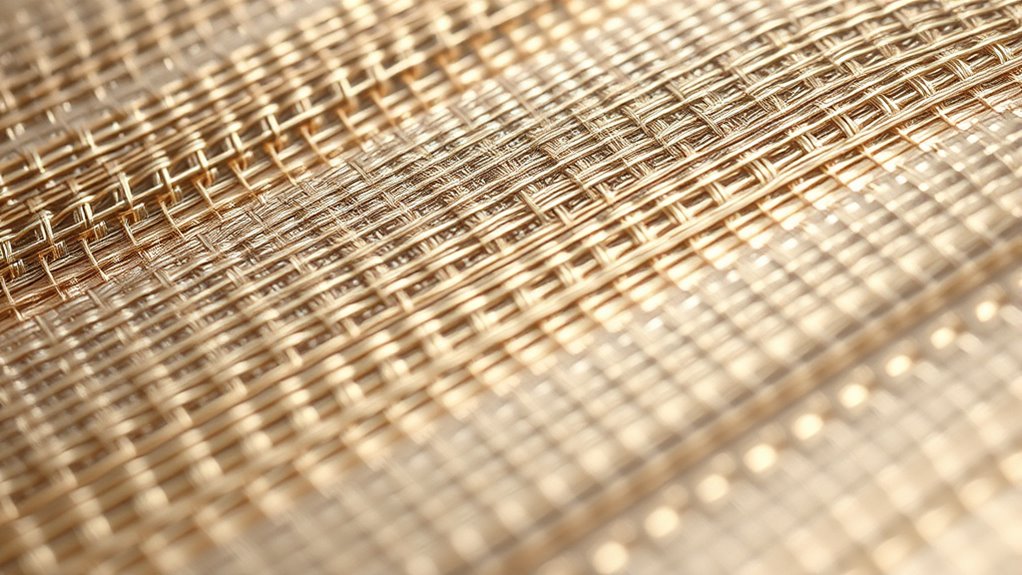

Materials and Thread Selection for High-KPSI Weaves

Selecting the right materials and threads is vital for achieving high-KPSI silk weaves, as they directly impact the fabric’s clarity, durability, and overall quality. When choosing silk threads, opt for fine, high-quality silk known for its consistent texture and strength. Silk dyeing techniques also play a pivotal role; using precise dyeing methods ensures vibrant, even color absorption without compromising thread integrity. Consider the following:

- Fine, multi-ply silk threads for smooth weaving

- Silk dyeing techniques that prevent color bleeding

- Threads with uniform thickness for consistent tension

- Colorfast dyes to preserve vibrancy

- Compatibility of dyeing methods with high-thread-count fabrics

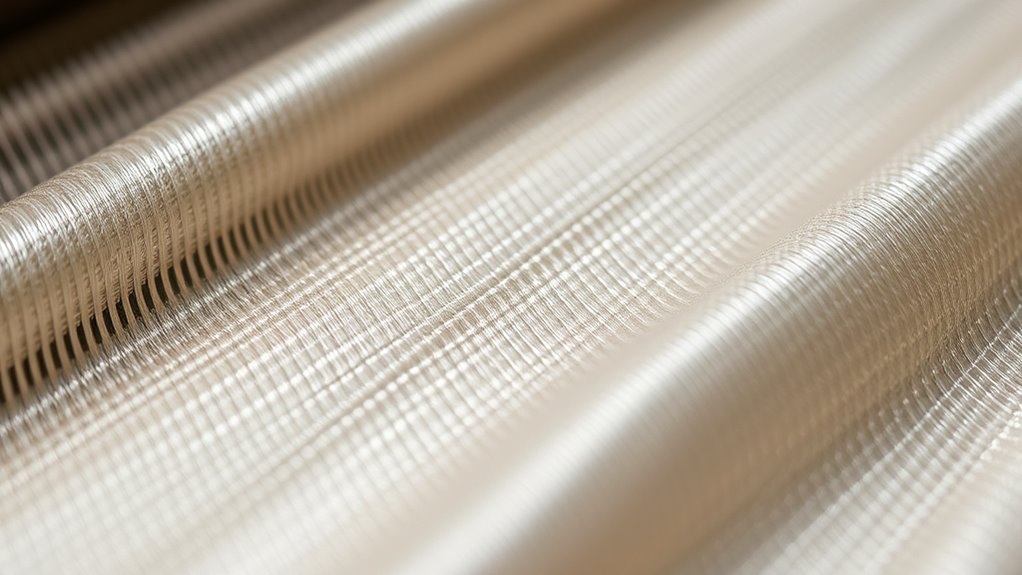

Visual and Tactile Characteristics of 1,200 KPSI Silk Fabrics

At 1,200 KPSI, silk fabrics exhibit an exceptionally smooth and lustrous surface that immediately catches the eye. The high density enhances the silk dyeing process, resulting in vibrant, deep colors with subtle depth and brilliance. You’ll notice how weaving patterns become more intricate and precise, showcasing the craft’s mastery. The fabric’s surface feels incredibly soft and cool to the touch, with a silky smoothness that reflects light effortlessly. The tight weave minimizes surface irregularities, emphasizing a uniform appearance and a mirror-like sheen. This level of craftsmanship creates a fabric that is both visually stunning and tactilely luxurious, making it perfect for high-end garments or accessories where every detail counts.

Challenges in Producing Ultra-Dense Silk Textiles

Achieving the flawless, mirror-like sheen of 1,200 KPSI silk fabrics involves overcoming significant production hurdles. One major challenge is mastering dyeing techniques that ensure even, vibrant color without compromising the fabric’s density. Ultra-dense silk demands precise control of dye penetration to maintain dye fastness, preventing fading over time. Additionally, the weaving process must be meticulously managed to avoid fiber distortion or damage. Handling such fine threads increases the risk of breakage, requiring advanced machinery and skilled craftsmanship. Consistent quality control is essential to prevent defects that can compromise both appearance and durability. Overcoming these hurdles demands innovation, patience, and expertise to produce silk textiles that are both visually stunning and long-lasting.

- Mastering dyeing techniques for uniform color

- Ensuring high dye fastness in dense fabrics

- Preventing fiber damage during weaving

- Maintaining consistent quality control

- Managing the delicate balance of density and durability

The Future of Silk Weaving: Innovations and Artistic Possibilities

The future of silk weaving holds exciting possibilities as technological advancements and artistic innovation converge to push the boundaries of what’s achievable. You’ll see new fiber dyeing techniques that produce richer, more vibrant colors, while pattern motifs become more intricate with digital design tools. These innovations allow you to experiment with complex textures and detailed imagery, transforming traditional silk art into modern masterpieces.

| Technique | Artistic Possibility |

|---|---|

| Advanced fiber dyeing | Customizable, vivid hues |

| Digital pattern design | Highly detailed motifs |

| Micro-weaving tech | Ultra-fine textures |

| Automated loom systems | Faster, precise weaving |

| Sustainable fibers | Eco-friendly art forms |

Frequently Asked Questions

How Long Does It Take to Produce a 1,200 KPSI Silk Weave?

Producing a 1,200 KPSI silk weave takes significant time due to thread intricacy and dye absorption. You’ll need careful planning to guarantee each thread is precisely woven and dyed, which can take weeks depending on complexity. The high thread count demands meticulous attention, as any mistake affects quality. So, expect a lengthy process that balances craftsmanship and patience to achieve the perfect silk-on-silk weave at this advanced level.

What Are the Environmental Impacts of Ultra-Dense Silk Weaving?

Imagine weaving a tapestry where every thread counts—ultra-dense silk weaving impacts the environment more than you might think. You can reduce this by embracing eco-friendly practices, like using sustainable resources and minimizing waste. This approach helps protect resource sustainability, ensuring your craftsmanship doesn’t come at nature’s expense. By consciously choosing eco-conscious methods, you create beauty that respects both artistry and the planet, weaving a future where luxury and sustainability go hand in hand.

Can These Techniques Be Applied to Other Natural Fibers?

You can definitely explore applying these weaving techniques to alternative fibers like hemp, linen, or bamboo. Their natural properties might benefit from ultra-dense weaving, enhancing durability and texture. By adapting these techniques, you not only expand the material options but also promote sustainability. It’s an innovative way to merge craftsmanship with eco-friendly practices, creating versatile textiles that push traditional boundaries while reducing environmental impacts.

How Do Artisans Ensure Consistency at Such High Knot Densities?

Imagine weaving a spider’s web—delicate yet precise. You guarantee consistency at high knot densities by meticulously controlling thread tension, preventing slack or tight spots. Quality control measures, like regular inspections and standardized techniques, act as your safety net. This combination keeps each knot uniform and the overall weave flawless, turning intricate craftsmanship into a seamless masterpiece. Your attention to detail transforms complex work into stunning, high-density textiles.

Are There Health Risks Involved in Working With High-Density Silk Threads?

You might wonder if working with high-density silk threads poses health risks. Occupational safety is crucial, so you should follow ergonomic practices to prevent strain or injuries. Using proper tools and taking regular breaks helps reduce risks. While silk itself isn’t harmful, prolonged repetitive motions can cause discomfort. Prioritizing safety measures ensures you work comfortably and sustainably, maintaining both your health and the quality of your craftsmanship.

Conclusion

Imagine your fingertips brushing a tapestry woven from a thousand stars—each thread a story, each knot a heartbeat. As you hold this 1,200 KPSI silk, you witness the fusion of tradition and innovation, like a delicate dance of light and shadow. This craftsmanship isn’t just fabric; it’s a living symbol of human ingenuity, weaving dreams into a dense, luminous fabric that whispers the future of silk artistry.