To treat acidic cellulose foundations, you’ll need to use deacidification methods that neutralize acids and stabilize pH levels. This involves applying alkaline agents like magnesium oxide or calcium carbonate powders through spray or brushing techniques, tailored to the material’s condition. Proper application is vital to guarantee even coverage and avoid damage. Monitoring the treatment’s effectiveness over time helps maintain the foundation’s integrity. Keep exploring to discover detailed strategies and best practices for lasting preservation.

Key Takeaways

- Proper deacidification involves neutralizing acids and buffering pH levels to prevent cellulose breakdown.

- Common agents include magnesium oxide and calcium carbonate powders, chosen for effectiveness and safety.

- Application methods include water-based sprays, brushes, and aerosol treatments, tailored to artifact condition.

- Monitoring pH and fiber condition over time ensures treatment durability and long-term stabilization.

- Selecting appropriate techniques depends on material sensitivity, size, environmental factors, and preservation goals.

Understanding Acidic Degradation in Cellulose Materials

Cellulose materials are vulnerable to acidic degradation, which accelerates their deterioration over time. When acids build up, they lower the pH level, causing the fibers to weaken and become brittle. To prevent this, pH balancing is essential. By neutralizing acids through acid neutralization processes, you can stabilize the material’s environment and slow deterioration. Understanding how acidity affects cellulose helps you identify early signs of damage and implement effective treatments. Maintaining a proper pH level ensures the cellulose remains stable and less prone to decay. Regular monitoring and targeted deacidification can markedly extend the lifespan of these materials, protecting your valuable structures. Ultimately, controlling acidity through proper pH balancing and acid neutralization is key to preservation and long-term stability.

Common Causes and Indicators of Acidity in Foundations

You might notice discoloration patterns on your foundation or nearby surfaces, which can signal acid-related damage. Persistent odors or dampness are also common clues that acidity is affecting your structure. Recognizing these indicators early can help you address issues before they worsen.

Visible Discoloration Patterns

Have you ever noticed uneven discoloration or dark streaks on a foundation’s surface? These visible patterns often signal underlying acidity issues. Look for:

- Areas where color bleeding causes pigments to spread beyond original boundaries

- Stain migration, where discoloration moves over time, indicating ongoing chemical reactions and acidic conditions

- Dark patches contrasting with lighter zones, suggesting localized acidity

- Faint ring-like formations around certain spots, hinting at moisture and pH shifts

- Uneven fading or blotchy patches that point to inconsistent deacidification

These discoloration patterns serve as visual clues of potential problems. Recognizing them early helps you determine if further testing or treatment is necessary. Additionally, AI-driven analysis can assist in identifying subtle patterns that may escape the naked eye. Understanding foundation chemistry and how it influences pH balance enables more accurate diagnosis and effective remediation. Incorporating knowledge of material properties can further improve the assessment process. Addressing these signs promptly prevents further damage and preserves your foundation’s integrity.

Persistent Odors or Dampness

Persistent odors or dampness in a foundation often signal underlying acidity issues that require immediate attention. When you notice a musty smell or persistent moisture, it’s a sign that your foundation may be experiencing high acidity levels, which can promote mold growth. To address this, focus on mold prevention by improving ventilation and removing excess moisture. Installing moisture barriers can also help block ground moisture from seeping into the foundation, reducing dampness. These steps not only prevent further acidity damage but also create a healthier environment inside your space. Using deacidification treatments specifically designed for cellulose foundations can neutralize acidity and protect structural materials. Proper air quality management can also help reduce indoor humidity that exacerbates these issues. If you ignore persistent odors or dampness, the acidity can accelerate deterioration of cellulose materials. Acting promptly with deacidification treatments and moisture control measures helps preserve your foundation’s integrity and prevents long-term damage. Additionally, understanding the chemical composition of your foundation materials can aid in selecting the most effective treatment options.

Chemical Principles Behind Deacidification Processes

The chemical principles behind deacidification processes revolve around neutralizing or buffering acidic components within fragile materials, such as paper or textiles. Your goal is to achieve pH buffering and chemical stabilization to prevent further deterioration. By introducing alkaline substances, you neutralize acids and maintain a stable pH level. This process involves understanding the chemistry of acids and bases, and how they interact with cellulose fibers. Proper application guarantees the material’s longevity without damaging its structure. Additionally, understanding asset division laws can inform best practices for conservation funding and resource allocation. The selection of appropriate alkaline agents is crucial to ensure effective neutralization without compromising material integrity. Employing testing methods to monitor pH levels during treatment ensures the process remains within safe and effective parameters. Incorporating chemical interactions knowledge helps optimize the deacidification process for different materials and conditions. Being aware of regional legal resources can also aid in securing appropriate support and guidance for conservation projects.

Types of Deacidification Agents and Their Applications

You need to understand the common deacidification agents and how they’re applied to protect materials. Different techniques exist, each with its own advantages and limitations. Knowing these options helps you choose the best approach for your specific needs. For example, some agents are designed specifically for cellulose preservation, ensuring that the material’s integrity is maintained over time. Additionally, selecting an appropriate deacidification method can help mitigate the effects of acid deterioration and extend the lifespan of the preserved materials. Understanding storage conditions is also crucial, as proper environmental controls can significantly slow down acid-related decay processes. Recognizing the importance of fathers’ influence can further inform how preservation techniques might be tailored to maintain the cultural significance of these materials.

Common Deacidification Agents

Deacidification agents play a crucial role in preserving paper, textiles, and other materials by neutralizing acids that cause deterioration. These agents include various chemical solutions designed to stabilize pH levels and prevent further decay. pH buffers are commonly used, maintaining an alkaline environment that halts acid progression. Alkaline sprays are applied directly to affected surfaces, offering quick neutralization. Some agents are water-based, allowing easy penetration into fibers, while others are solvent-based for targeted treatment. You may also encounter magnesium oxide and calcium carbonate powders, which serve as buffering agents. These materials work by releasing ions that neutralize acids and raise pH. Choosing the right deacidification agent depends on the material type, condition, and preservation goals.

Application Techniques Employed

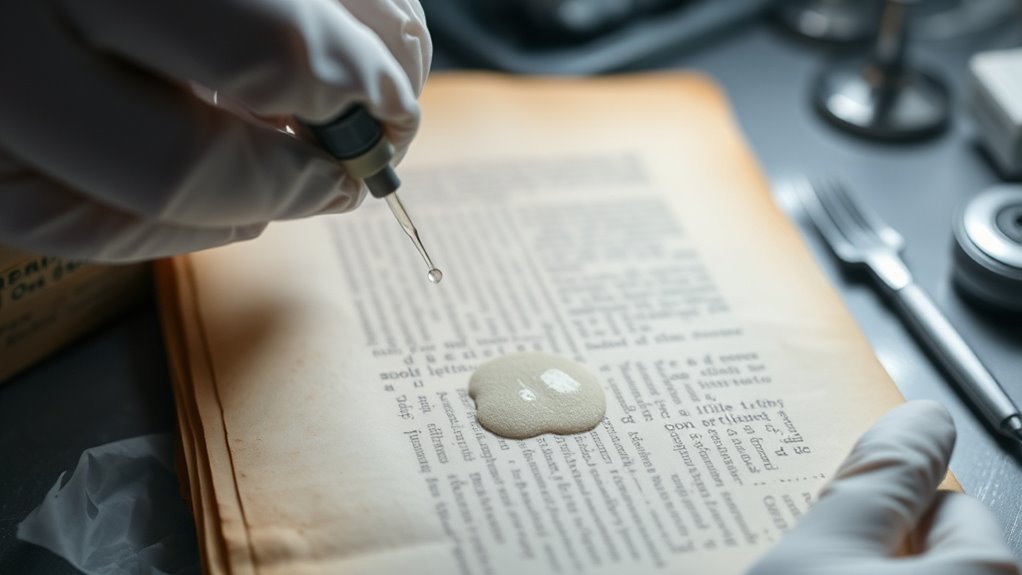

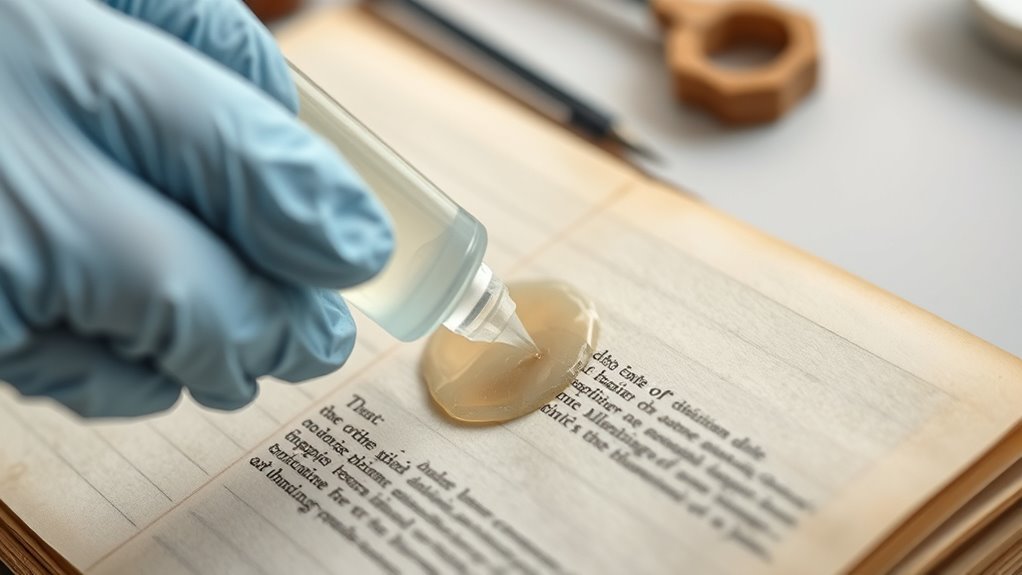

Applying deacidification agents effectively depends on selecting the appropriate type for the material and the specific preservation needs. You can use spray application to evenly distribute liquid agents across large or delicate surfaces, ensuring thorough coverage without physical contact. This method minimizes the risk of damage and helps penetrate the material’s fibers. Alternatively, brush techniques allow for targeted treatment, giving you precise control, especially on smaller or more detailed areas. With brushes, you can carefully apply the deacidification solution, working into crevices and uneven surfaces. Both methods require careful handling to avoid over-saturation or uneven coverage. Your choice between spray application and brush techniques depends on the material’s condition, size, and the preservation goals you aim to achieve.

Pros and Cons

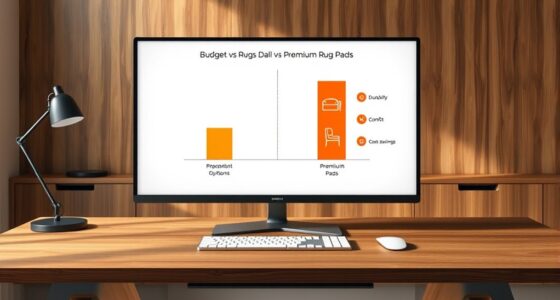

Different types of deacidification agents offer distinct advantages and limitations depending on their chemical composition and application methods. You should consider environmental impacts and cost considerations when choosing an agent.

- Alkali metal hydroxides are effective but may pose environmental risks if not properly managed.

- Calcium carbonate is eco-friendly and stable but can be costly.

- Magnesium oxide offers good buffering capacity with minimal environmental concerns.

- Ethical concerns arise with some chemical solvents, affecting their suitability.

- Application costs vary, influencing choices based on your budget and project scope.

Balancing environmental impacts and costs helps ensure you select a deacidification agent that preserves the integrity of cellulose foundations without causing undue harm or financial strain.

Techniques for Applying Deacidification Treatments

When selecting a technique for deacidification, the goal is to neutralize acids effectively while minimizing potential damage to the artifact. You should consider different application methods, such as aqueous, non-aqueous, or aerosol sprays, depending on the object’s condition and composition. Aqueous methods involve immersing or applying liquids carefully to ensure uniform coverage, but they require strict control to prevent over-saturation. Non-aqueous techniques, like microemulsions or solvent-based sprays, reduce moisture risk and improve treatment safety for sensitive materials. Aerosol applications offer quick, localized treatment, but you must handle them carefully to avoid uneven application. Always prioritize treatment safety by choosing methods that balance effectiveness with the preservation of the artifact’s integrity.

Evaluating the Effectiveness and Longevity of Treatments

After selecting an appropriate deacidification technique, it’s important to assess how well the treatment performs over time. You need to monitor its effectiveness and durability to guarantee the cellulose remains protected. Consider the environmental impact, as some treatments may pose ecological risks or generate hazardous waste. Cost effectiveness also plays a vital role, helping you determine if the benefits justify the investment. Regular testing, such as pH measurements and microscopy, provides insights into ongoing performance. Additionally, observe any changes in physical appearance or structural integrity. Long-term studies help predict how treatments hold up under varying environmental conditions. By evaluating these factors, you ensure your deacidification efforts remain sustainable, safe, and economically viable over time.

Best Practices for Preserving Cellulose-Based Artifacts

Preserving cellulose-based artifacts requires a proactive approach that addresses environmental control, handling, and storage conditions. Understanding the historical context helps you appreciate how past exposure to pollutants, humidity, and light caused deterioration. To minimize environmental impacts, you should maintain stable temperature and humidity levels, avoid direct sunlight, and use proper storage materials. Handle artifacts with clean gloves to prevent oils and dirt from accelerating decay. Store items flat in acid-free, archival-quality containers to prevent physical stress. Regularly monitor environmental conditions and conduct condition assessments. Educate yourself on the artifact’s history to inform preservation strategies. By combining environmental management with careful handling, you extend the lifespan of cellulose artifacts and protect their historical significance for future generations.

Frequently Asked Questions

What Are the Environmental Impacts of Deacidification Chemicals?

When you consider deacidification chemicals, environmental concerns come to mind, especially regarding chemical toxicity and potential pollution. These treatments can release harmful substances into the environment if not handled properly. You should be aware of the risks, as improper use or disposal might affect water, soil, and air quality. It is crucial to use eco-friendly options and follow safety guidelines to minimize negative impacts on the environment.

How Do Deacidification Treatments Affect the Long-Term Stability of Cellulose?

Think of your fragile pages as ancient trees, vulnerable to acid rain that weakens their core. Deacidification acts like a protective shield, neutralizing acids in acidic paper and extending conservation longevity. It stabilizes the cellulose fibers, preventing deterioration over time. This treatment enhances long-term stability, ensuring your treasured documents remain resilient and preserved for future generations, much like a mighty oak standing firm against the storms of time.

Are There Non-Chemical Methods for Neutralizing Acidity in Foundations?

You might wonder if there are non-chemical ways to neutralize acidity in foundations. Biological methods use beneficial microbes to break down acids naturally, offering an eco-friendly approach. Mechanical neutralization involves physically removing or buffering acidic materials, providing immediate stabilization without chemicals. These strategies can complement traditional treatments, helping preserve your foundation’s integrity while reducing chemical reliance. Your goal should be choosing a method that suits your specific needs and long-term preservation goals.

How Can One Identify the Best Deacidification Method for Specific Artifacts?

This is the most vital decision you’ll make—choosing the perfect deacidification method can feel like finding a needle in a haystack! To identify the best approach, you should perform pH testing to determine the artifact’s acidity level. Then, evaluate treatment compatibility to guarantee the method won’t damage your object. Carefully consider these steps, and you’ll confidently select the most effective, safest deacidification process tailored to your artifact’s needs.

What Are the Safety Precautions During Deacidification Application?

When applying deacidification, you need to prioritize handling chemical safety by working in well-ventilated areas and following manufacturer instructions. Always wear appropriate personal protective equipment, such as gloves, goggles, and masks, to prevent chemical exposure. Make certain you’re trained in proper handling procedures, keep a clean workspace, and have emergency supplies nearby. These precautions help protect you from potential hazards and ensure a safe, effective deacidification process.

Conclusion

So, next time your ancient paper or fabric starts whispering secrets of acidity, remember you’re the hero armed with deacidification magic. Don’t just stand there, hoping it’ll fix itself—grab those treatments, apply them like a pro, and keep your cellulose treasures from turning to dust. Because, honestly, who wants their priceless artifacts to become history’s forgotten crumbs? Stay vigilant, stay savvy, and let your preservation skills shine—before it’s just a pile of old, acidic excuses.